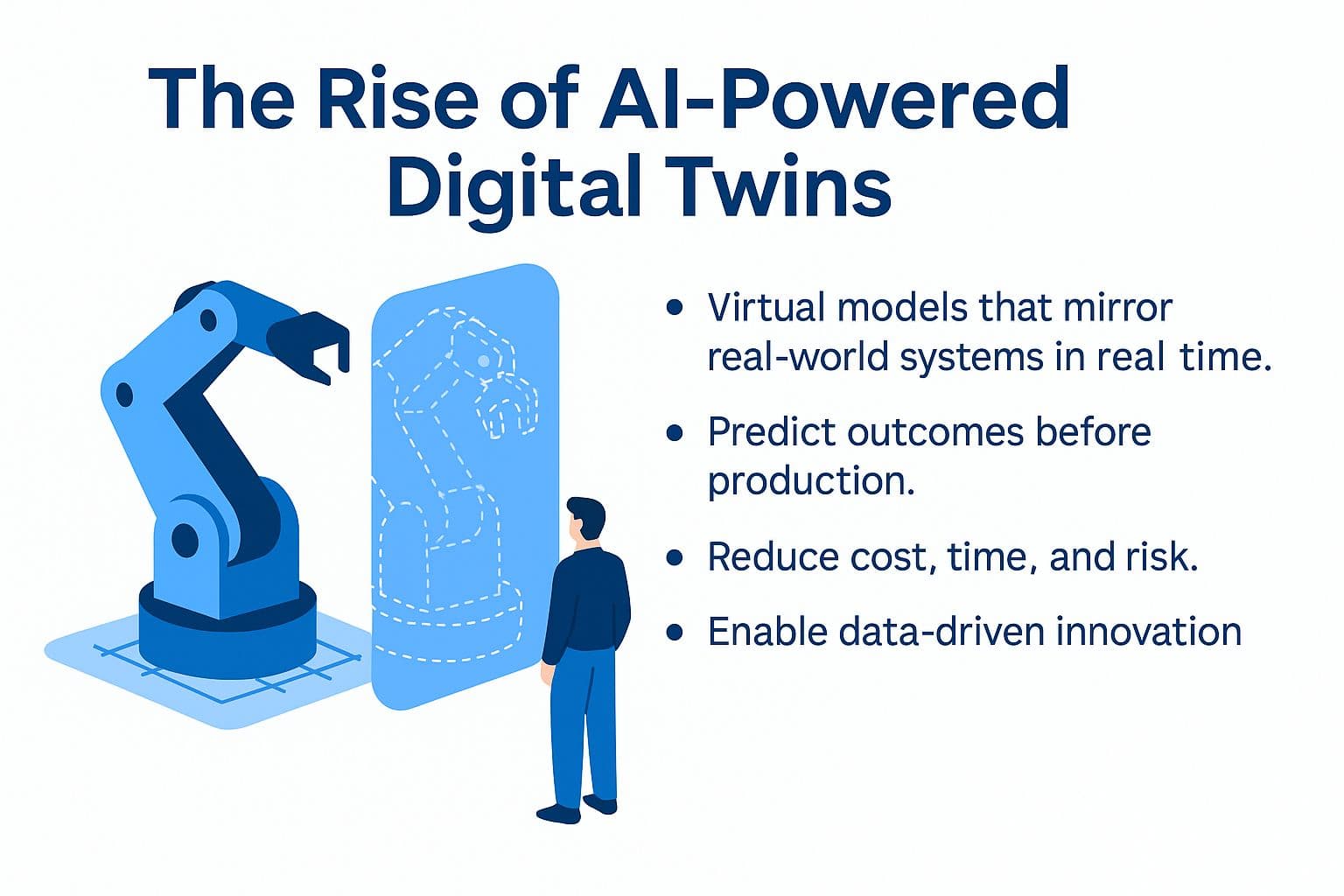

Product engineering is undergoing a significant transformation. It is the era where digital twins are coming to the forefront. Nowadays, Virtual models of real-world systems will thus determine the product's lifecycle, including conception, testing, and adaptation. Also, engineers can now create smart digital twins that predict every possible outcome before one piece is made, which is better than working with mere physical prototypes.

Do you know that the digital twin is a combination of data, sensors, and simulation? It represents a product, process, or system in the digital world as a living entity. The incorporation of AI and generative AI into the picture results in these twins beginning to think and evolve, further providing insights that are far beyond normal testing. The numbers illustrate the point clearly: the digital twin market around the world is already worth close to US$14.46 billion by 2024 and is expected to continue on a sharp upward trajectory until 2028.

In this blog, we’ll take a close look at how product engineering is evolving with the rise of AI-driven digital twins. We’ll explore how their architecture works, what makes them valuable, and the growing influence of generative AI in shaping the next wave of innovation. By the end, you’ll see how these intelligent systems are setting the stage for a faster, smarter, and more connected approach to engineering in 2025 and beyond.

The Rise of Smart Twins: How AI is Giving Engineering a New Brain

A digital twin corresponds to a virtual model that imitates a physical asset, process, or system in real-time, and it literally matches the performance of its real-world counterpart. The digital twin gathers data from sensors, IoT devices, and connected systems for simulating the entire lifecycle, foreseeing possible failures, and making better decisions. This architectural setup integrates data from different sources, including a simulation engine and feedback setup, thus forming a closed system where insights from the virtual world directly affect the real world.

When digital twins are used by AI and generative AI, they turn into exceptionally intelligent and predictive systems. Also, AI makes it possible for the digital twin to analyse vast amounts of data, see hidden trends, and predict events that would otherwise be unknown. Generative AI takes things a step further; it can produce synthetic data, draft entirely new prototypes, and test edge scenarios within seconds. As many industry leaders point out, the combination of generative AI and digital twins is reshaping how organisations work, and that change is already well underway.

This signifies that in product engineering, the methods of prototypes, testing, and lifecycle modelling are all going to be a lot smarter and will be done through data. Today, engineers can run simulations to optimise materials and to improve performance before the manufacturing process starts. Consequently, the evolution of products comes with faster innovation, lower costs to work, but to grow intelligently throughout their life.

The Real Benefits of Digital Twins for Today’s Product Engineers

Let’s pause for a second. Why should digital twins even matter to you as a product engineer? Here’s where things get interesting.

When you bring AI, real-time data, and simulation together, you’re not just testing designs; you’re creating a system that learns, predicts, and improves faster than any traditional process ever could.

Key Benefits of Digital Twins in Product Design & Engineering:

- Faster Design Iteration & Time-to-Market: By utilising digital twins, you can conduct dozens of testing scenarios digitally, which will further result in a major reduction of the development process and quicker delivery of your products to the market.

- Reduced Cost and Risk: Prototype simulation on a computer leads to digital testing, which is much cheaper than traditional physical testing; thus saves the process of time, materials, and funds as much as possible.

- Predictive Maintenance & Lifecycle Optimisation: It acts as a digital twin for your product to monitor performance parameters continuously; thus, the occurrence of the problem will be predicted, and the maintenance schedule will be optimally planned.

- Better Decision-Making via Data Insights: With IoT sensors feeding real-time analytics, you get a live view of product performance, so you can act faster, fix smarter, and make every engineering decision count.

- Better Customer Experience & Customisation: Digital twins are used to simulate the way customers buy products and then create the exact experience based on the actual use patterns.

Furthermore, the U.S. market for AI-based simulations and digital twins alone was worth $1.04 billion in 2024, with a growth rate of 34.8%, further indicating that this technology is being adopted widely and quickly.

What Really Brings a Digital Twin to Life?

You know what really brings a digital twin to life? When it’s fully connected to the real thing. Your product, the IoT sensors keeping tabs on it, and the real-time data flows every second. That’s when it stops being just a model and starts acting like a living system.

In a smart digital twin setup, AI and generative AI are the driving forces. They help you test outcomes, explore rare edge cases, and even simulate what-if situations you’d never be able to try in the real world. It’s like having a lab that never sleeps, constantly learning and improving alongside your product.

Now, let’s break down the main layers that make this whole system tick.

1. Real-World Connection

This is the part where the digital twin links to the real world. The use of IoT devices and edge sensors is done to collect live data, which further in turn, gives the user the ability to simulate product behaviour correctly and even in real time.

2. Constant Data Flow

Your digital twin is fed continuously by telemetry and historical logs, which further keep it updated and let you check anomalies, perform experiments, and also make quicker engineering decisions.

3. The Brain Behind It

Your digital twin’s brain utilises physics-based models, ML algorithms, and generative AI. It is the place where forecasts are made, edge cases are investigated, and synthetic scenarios are developed to improve design choices.

4. Learning Through Feedback

Your digital twin is not only a spectator but also an actor. The simulation further provides insights that can be used to update the physical product or influence design improvements, thus helping you in performance and lifecycle planning optimisation.

5. Turning Data Into Insight

Having your twin is made possible by dashboards, AR, and VR interfaces. You can easily engage with results, experiment with choices, and share insights with your team without any hassle.

Also Read: Top 10 AI Startup Trends to Watch Out in 2025

Top Real-World Use Cases of AI-Driven Digital Twins Across Industries

What about the practical application of these concepts? AI-driven digital twins are not just a dream of the future; they are being used in different sectors to make the problems easier, make the solutions clearer, and provide more insights. If the question "How is AI used in digital twins?" has crossed your mind, these scenarios will definitely clear your doubt.

1. Smarter Factories with Digital Twins

Factories have the issue of unplanned downtime, expensive maintenance, and slow design iteration. By building digital twins of the devices, the engineers can test the operations, foresee the breakdowns, and plan the maintenance more quickly.

2. Digital Twins in Healthcare and MedTech

Personalised diagnostics and device performance are vital in healthcare. Also, hospitals and medical device manufacturers utilise digital twins in healthcare to mimic patient-specific treatments or track the device's performance live.

3. Smarter Products through AI Twins

Consumer electronics and IoT devices are prone to warranty claims, usage problems, or sudden failures. To tackle these issues, companies are creating digital twins that can represent the whole device lifecycle, user interaction, and even the possible points of failure.

However, the advantages are enormous, but the truth is, the use of AI-powered digital twins is not without its challenges. From data stream integration to simulation scaling, AIproduct engineering teams will have to confront difficulties before gaining complete access to this technology's power.

Think Digital Twins are Easy? Here’s the Catch

You’ve probably realised by now that AI-based digital twins sound like a total game-changer for product engineering, and they are. But here’s the thing: getting them right isn’t simple. From messy data to missing skills, there are a few roadblocks you’ll need to tackle before your twin becomes a fully capable, high-performing system.

1. Data Quality & Integration

The quality of your twin is directly proportional to the quality of data it gets. Sensor data might differ from one another, and older software applications might not interact properly. Dirty and sporadic data flow, which further results in your twin being incapable of giving you correct insights and forecasts.

2. Skill Gap in Your Team

Creating and even the cost of a twin requires not only engineers and data scientists but also professionals in the simulations. Moreover, you need your people to accept the new working style. Otherwise, the process of adoption will be slow, and no new insights will come out.

3. Security and Compliance

Digital twins almost always show sensitive assets; thus, security against hackers, access control, and even data governance and compliance with regulations have to be absolute priorities. The digital twin needs to be secured as well as treated equally to the real product it depicts.

4. Cost and Complexity

The whole process of creating the infrastructure to constantly rerun the simulations and scaling up the operations could become very costly as well as very technically difficult. Hence, a very clear and well-detailed plan is required to prevent going over the budget while still being able to realise full value

5. Practical Strategies

Pilot projects for starting small and implementing a modular architecture that will further grow along with you, and retraining your team are some recommended strategies. This, in turn, minimises the risk, gains your project credibility, and you will be in a position to use the AI-powered digital twins effectively.

Also, market forecasts show the global digital twin market growing from US$24.97 billion in 2024 to US$155.84 billion by 2030, at a CAGR of 34.2%, which proves the potential, but only if you navigate these challenges smartly.

What’s Changing for Product Engineers in 2025?

Let’s be honest, staying ahead in AI-native product engineering means knowing what’s coming next. And AI-powered digital twins? They’re leading that next wave. The trends you’re about to see aren’t just buzzwords; they’re changing how you plan, design, and scale every new product.

1. Smarter Engineering with AI

Generative AI takes the lead in the journey towards the smarter twin. The models you work with now can not only improve you but will also come up with simulations for complex edge cases and even redesign their parts before they are tested physically. This translates into faster iterations and more informed engineering decisions.

2. Seeing and Experiencing Your Product in 3D

AR and VR in business open a new door where you can actually be present in your digital twin. You can walk through the designs, play with the interactions, and see the workflows as if you were part of the product, a radical shift in your product engineering process.

3. Real-Time Twin Insights Closer to Action

Deploying twins at the edge means that data processing is kept very close to the source. Also, real-time insights are received immediately, allowing faster responses and smooth integration across the entire product lifecycle.

4. Designing Intelligent Products

Twins are now able to monitor the carbon footprint, optimise the use of materials, and even simulate eco-friendly alternatives. This means that you can design products that are not only smarter but also greener.

5. Easy-to-Use Platforms

There are now more companies that provide twin platforms as Software as a Service (SaaS). You can easily plug in, scale at the same time, and receive the advanced analytics without having to go through the whole process of building everything from scratch.

6. Without Complex Code

The deployment of a twin no longer requires a lot of heavy coding work. Low-code AI agents or no-code platforms allow your team to quickly create, test, and iterate on twins, thus keeping the development agile and responsive.

This momentum is evident in the market worldwide of the digital twin ecosystem, which is estimated to achieve USD 412 billion by the year 2033 with a CAGR of ~36.9%, which indicates the enormous growth potential.

Actionable Steps for Product Engineers & PMs

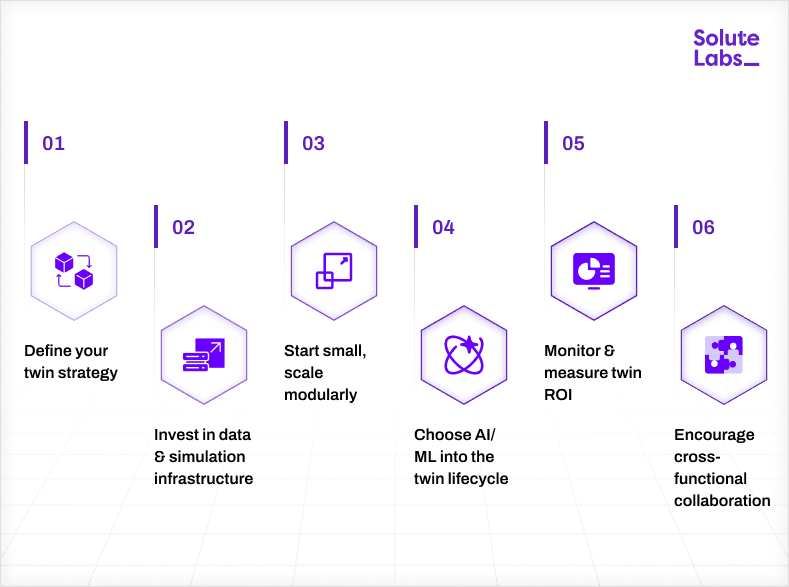

You’ve reached the point where you’re ready to actually use AI-powered digital twins, not just read about them. Think of this as your quick-start checklist. It’ll help you turn all those benefits we’ve talked about into measurable results.

Follow these steps, and you’ll move from testing theory to building smarter, more strategic digital products in real time:-

- Define your twin strategy - Align twin initiatives with your product roadmap and set measurable goals.

- Invest in data & simulation infrastructure - Make sure that your twin gets clean, real-time data and strong simulation capacity.

- Start small, scale modularly - Pilot projects allow you to test your assumptions and grow without completely redesigning your systems.

- Choose AI/ML into the twin lifecycle - Predictive analytics and generative AI can be used to make your twin better and better.

- Monitor & measure twin ROI - Monitor metrics like time-to-market, cost savings, and performance improvements.

- Encourage cross-functional collaboration - Bring together the engineering, data, and business teams for quicker insights and better decisions.

When you stick to this checklist, your digital twins stop being experiments and start becoming the backbone of your entire product strategy. You’ll build smarter, faster, and with more precision, turning every project into proof that AI and data-driven engineering actually work.

Conclusion

Here’s the thing: AI-powered digital twins aren’t just another tech trend. They’re quietly reshaping how products are designed, tested, and improved long before they ever hit production. By combining AI with digital twin technology, you can predict outcomes, explore endless design possibilities, and fix problems before they even happen. It’s a smarter, faster, and more intuitive way to build one that’s turning traditional product engineering into something truly intelligent.

At the end of the day, digital twins in product engineering aren’t just a tech upgrade; they’re a strategic advantage. If you’re ready to bring that level of intelligence into your product ecosystem, SoluteLabs can help. Our team builds AI-powered systems that make your engineering smarter and your outcomes sharper. Estimate your twin ROI → Get a free assessment today!